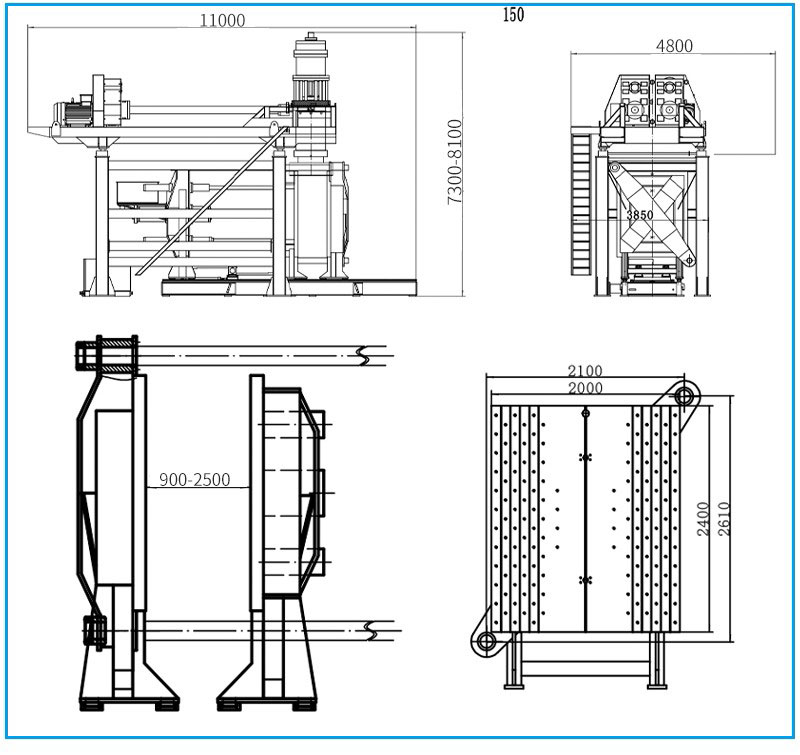

TTBA-150 Blow Molding Machine

This machine is composed of frame, extruder, material storage die head, die closing mechanism, blowing device, manipulator, cooling device, safety protection device, electrical control system, hydraulic control system and pneumatic control system. Mainly suitable for processing PE PP ,ABS and other hollow products as raw materials.

Product volume: 3000L

Machine dimensions (length x width x height):

11m x 4.8m (including manipulator) x 7.3/8.1m

Product technical parameters

(1) The extruder requires high production efficiency, good plasticizing quality, uniform color mixing and uniform color production of hollow products.

(2) Suitable for processing powder, granule, recycled material, color masterbatch mixture.

(3) Wide adaptability to raw materials.

(4) The proportion of recycled material is wide.

Technical parameter:

(1) Screw diameter: 120x2mm.

(2) Length- diameter ratio: 27:1. With ZLYJ330 type gear box

(3) Screw material: high-quality nitride steel, nitride surface treatment, nitride layer thickness of 0.4mm, hardness HV≥900.

(4) Barrel: high quality nitride steel 38CrMoAIA is selected. The inner surface is nitrided with hard-ness HV≥900.

(5) Driving mode: ac motor, frequency conversion automatic speed regulation, to keep the normal production of the stranded material does not stop, motor and gearbox belt connection.

(6) Driving power 110x2KW

(7) Screw speed: 0-60r/min low speed efficient screw.

(8)Temperature control: automatic temperature control module, can realize PID precision control

(9) Heating method: casting aluminum and mica heating ring or ceramic and mica heating ring

(10) Heating section: 6×2 sections of heating, temperature detection device

(11) Cooling mode: air cooling

(12) Hopper holder: circulating water cooling, cooling water flow can be controlled

(13) Plasticizing capacity: about 350×2KG/H HDPE

(14) Heating power of barrel: 82KW

Die system

Features: The storage cylinder part after electroplating polishing

(1) The mold head flow channel structure adopts foreign advanced plastic melt flow analysis software analysis and design, the mold core flow channel and the middle ring as a whole without dead Angle, the melt compound in the mold head, into the storage cylinder, formed material embryo strength is good, fast color change

(2) The area of servo cylinder and injection cylinder is large to ensure that the injection force and servo force meet the processing needs of high viscosity high molecular weight HIGH density polyethylene when the material embryo is formed

(3) The main parts of the storage cylinder, flow channel and mouth die are 38CrMo

(4) Cylinder seal adopts new sealing structure to ensure good sealing and long service life

(5) The heating ring of die head adopts mica heating ring. Special structure design, ensure that the heating ring and die head close, high heat transfer efficiency, long service life

(6) Using wall thickness control technology, can effectively control the weight of products, improve the performance of products

Technical parameters of die head system

(1) Die head model: 82 MT maximum die diameter 1200mm

(2) Heating power of die head: 93KW

(3) One time maximum discharge: about 82Kg

(4) Heating method: casting aluminum and mica heating ring or ceramic and mica heating ring

(5) Temperature control: temperature control module

(6) Mouth mold size: customer provided (or according to the sample)

(7) Hydraulic drive power :37KW

(8) Average energy consumption of the whole machine: 160KW/H

(9) The use of cable model: copper core wire 150 square, three- phase five lines

3. Open and close die system

(1) Template size (width X height) ; 2000mmX 2400mm pull arm type bulk modulus

(2) Rod spacing (width x height) : 2000mmx 2400mm

(3) Template spacing: 900mm-2500mm mold change operation is simple

(4) Maximum modulus (width/height): 1600 mm/2600mm

(5) Clamping force: 400KN Actual product flat area maximum 3.2 square

4. Manipulator

(1) With manipulator advance and retreat action and clamping relaxation action, speed can be adjusted

(2) Clamping diameter: 1050mm

(3) Advance and retreat stroke: 2100mm

5, multi-function down blowing

(1) Down blowing device has automatic up and down adjustment function

(2) The maximum width of automatic encapsulation is 550mm

(3) The size of support material can be adjusted to 160mm -1560mm

(4) Down blowing device can be adjusted left and right, so as to adjust the mold center

6. Hydraulic control system

(1) Working pressure of low-pressure system: 10Mpa

(2) Working pressure of high pressure system: 18Mpa

(3) High and low pressure hybrid power, can realize low speed high pressure and low pressure,

high speed high pressure and low pressure.

Sample drawings